Rapid Cycling of Control Switch Damages or Destroys Large Pump or Compressor Motors

Issue:

How do I prevent a Bouncing Control Switch Due to Splashing Water from Rapidly Energizing One Load and Then the Other?

Solution/Resolution:

|

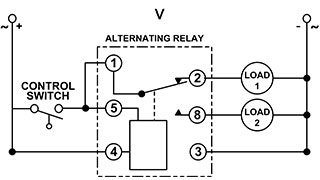

In Figure A, a single Control Switch could be susceptible to splashing water which would cause rapid opening & closing of the Control Switch. Each time this happens, one Load is rapidly energized and de-energized, then second Load is rapidly energized and then de-energized. This rapid cycling would continue until the liquid level remained consistently above or below the Control Switch. Eventually, this action would damage the pump motors requiring an expensive repair or replacement. |

Figure A |

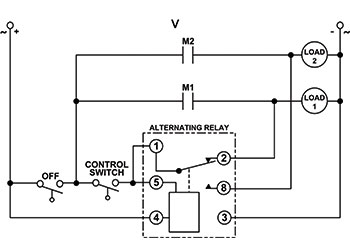

| To eliminate any bounce condition of the Control Switch, the addition of a second switch (OFF) along with two auxiliary contacts is recommended as shown in Figure B. When the OFF switch closes first followed by the Control Switch, LOAD 1 or LOAD 2 is energized depending on the position of the alternating relay. This also closes the appropriate auxiliary contact M1 or M2. Even if the Control Switch opens & closes rapidly due to splashing water, LOAD 1 or LOAD 2 will remain energized due to the M1 or M2 auxiliary contact keeping it ON. Only the opening of the OFF switch can turn off LOAD 1 or LOAD 2 and toggle the alternating relay to the other position. |  Figure B |

For more information, please contact Macromatic at 800-238-7474..

Recent Articles for:

Alternating Relays

- Jun2020 Triplex Pump Control Using Cost-saving Alternating Relays

- Aug2019 What is Sequence On – Simultaneous Off (S.O.S.O. or SOSO) Operation on Pump Control?

- Aug2019 Typical Applications for Alternating Relays

- Nov2018 Using Alternating Relays with DC Input Voltages

- Jan2018 Using DPDT Cross-Wired Alternating Relays with HIGH-LOW Float Switches