Using Liquid Level Control Relays

Liquid Level Control Relays detect & control levels of conductive liquids such as fresh water, seawater, sewage & coffee (see table below for other liquids). They provide a low voltage signal (typically 5VDC pulsed to prevent electroplating issues) to a probe or probes and a common connection on the tank. The conductive properties of the liquid complete a circuit between a probe and the common connection when the liquid comes in contact with both. These relays sense the resistance value between the probe(s) and the common. They compare the value of the measured resistance with the setpoint of the adjustable potentiometer provided on the product. Typical resistance values of various liquids are shown in the table below.

| Type of Liquid | Resistance (ohms)/cm |

|---|---|

| Fresh Water | 5K |

| Salt Water | 2.2K |

| Wastewater (Sewage) | 0.5-2K |

| Well Water | 2-5K |

| Condensed Water | 18K |

| Coffee | 2.2K |

| Fruit Juice | 1K |

| Milk | 1K |

| Wine & Beer | 2.2K |

| Soap Foam | 18K |

| Cement Slurry | 5K |

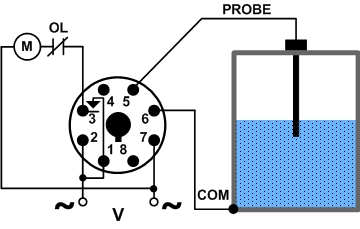

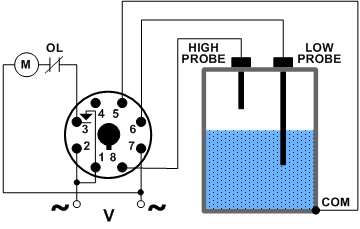

The probes are typically stainless steel corrosion-resistant electrodes with no moving parts. They can be made of any conductive material in any shape or size. Connections as shown below are made between the Liquid Level Control Relay terminals, the probe or probes, and the common connection. If the tank is non-conductive or insulated, an additional probe must be installed as the common connection where it will always be submerged.

Depending on the specific function of the unit (pump up or pump down, single or dual probe), the SPDT output is used to turn on or off pumps, solenoids or valves to lower, raise or maintain the level of the liquid in the tank. It can also provide an alarm indication if the liquid is present or not.

Typical applications include the draining or filling of a tank, low level cutoff (boilers or heaters), pump shut down and alarms for presence of liquids.

Operation of Liquid Level Control Relays

Single Probe

Pump Up (Fill): When the liquid level falls below the probe, a fixed time delay begins & the LED flashes Red. This time delay prevents rapid cycling of the output relay & its load. At the end of the time delay, the output relay energizes & the LED is Red ON. The pump is ON to fill the tank. The relay remains energized until the liquid level rises & touches the probe. The output relay de-energizes, turning off the pump, and remains de-energized & the LED is Green ON until the liquid level falls below the probe.

Pump Down (Drain): When the liquid level rises & touches the probe, a fixed time delay begins & the LED flashes Red. This time delay prevents rapid cycling of the output relay & its load. At the end of the time delay, the output relay energizes & the LED is Red ON. The pump is ON to drain the tank. The relay remains energized until the liquid level falls below the probe level. The output relay de-energizes, turning off the pump, and remains de-energized & the LED is Green ON until the liquid level rises & touches the probe.

Why Use Single Probe Relays?

To maintain the liquid around a single level. The differential above (pump down) or above (pump up) the single level is dictated by the time delay before the relay energizes–a longer delay allows a greater variation in the level; a shorter delay gives a smaller variation.

Dual Probe

Pump Up (Fill): When the liquid level falls below the low level probe, the output relay energizes & the LED is Red ON. The pump is ON to fill the tank. The relay remains energized until the liquid level rises & touches the high level probe. The output relay de-energizes, turning off the pump, and remains de-energized & the LED is Green ON until the liquid level again falls below the low level probe.

Pump Down (Drain): When the liquid level rises & touches the high level probe, the output relay energizes & the LED is Red ON. The pump is ON to drain the tank. The relay remains energized until the liquid level falls below the low level probe. The output relay de-energizes, turning off the pump, and remains de-energized & the LED is Green ON until the liquid level rises & touches the high level probe.

Why Use Dual Probe Relays?

To raise or lower the liquid between two levels–a HIGH & a LOW level. Using a dual probe level control relay typically allows for a greater variation between levels than a single probe relay.

For additional information, please contact Macromatic Controls.

Recent Articles for:

Liquid Level Control Relays