Connection of Pump Seal Failure (Seal Leak) Relays in Submersible Pump Applications

Issue:

I need to know how to install and connect the wiring for my seal leak probe to a Macromatic Seal Failure Relay.

Solution/Resolution:

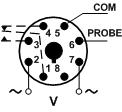

Making the right connections: Seal leak probes are typically built into, or attached to, the submersible pump. Most pumps will have only a single seal leak probe, but may have one or two wires (or terminals) to connect the Seal Failure Relay to the probe. If your pump has only one wire (or terminal), it should be connected to the "Probe" terminal of the Seal Leak Relay. The "COM" terminal of the Seal Failure Relay will need to be connected to the metal chassis of the submersible pump (if the pump chassis is already connected to a common or ground, the "COM" terminal can be connected there as well). If your pump has two wires (or terminals) for a single seal leak probe, connect one to the "PROBE" and the other to the "COM" terminals of the Seal Failure Relay. The polarity does not matter in most installations, but always follow markings and instructions provided on or together with the pump.

|

|

|

Maximum length of probe wires: The seal leak probe is typically located a considerable distance away from the Seal Failure Relay. In order to ensure proper operation, we recommend that you limit the length of the wiring connecting the probe to the Seal Failure Relay as shown in the table below. (Please note that "maximum distance" is the total length of the wire running to the probe and back again.)

| Wire Size (AWG) | Maximum Distance (total length of wire to & from probe) | |

| (Feet) | (Meters) | |

| 12 | 6,927 | 2111 |

| 13 | 5,492 | 1,674 |

| 14 | 4,356 | 1,328 |

| 15 | 3,455 | 1,053 |

| 16 | 2,739 | 835 |

| 17 | 2,172 | 662 |

| 18 | 1,723 | 525 |

| 19 | 1,366 | 416 |

| 20 | 1,084 | 330 |

| 21 | 859 | 262 |

| 22 | 682 | 208 |

Probe Wiring Installation: The seal leak probe wiring carries a sensitive analog signal and requires special precautions to prevent problems with electrical interference from other equipment. Macromatic Seal Failure Relays have specialized filter circuitry to reduce this interference, but we strongly recommend that you also follow the practices listed below. These practices may help prevent interference, and are listed in order of importance:

- We recommend against running the probe wires inside the same conduit with the wiring to the pump. The use of separate conduits is preferred.

- Locate probe wiring away from any other higher voltage/current wiring, such as the power wiring to the pump itself. A separation of at least 3 feet in open air is recommended.

- Utilize shielded cabling for probe wires; terminate the shield to ground at one end.

Recent Articles for:

Seal Leakage & Temperature Relays

- Mar2017 Replacing a Crouzet PNR110A with a Macromatic SFP120A100 Seal Leak Relay

- Feb2017 Where are Seal Leakage Relays Used?

- Jan2017 Macromatic’s New TCF Series Drop-In Replacement for MPE’s PMR1 & PMR3 Has More Advantages

- Aug2015 Connection of Pump Seal Failure (Seal Leak) Relays in Submersible Pump Applications