Where are Seal Leakage Relays Used?

Bearings are one of the most important components of electric motors. Normally, they are designed to operate for many years. Yet, more than half of motor failures are caused by bearing failure. The most common causes of premature bearing failure are lubrication loss and contamination ingress.

That is why all motors have bearing seals. They have two main functions: to prevent lubricating oil from leaking out; and to prevent dust, water and other contaminants from entering the bearing. Bearings should be adequately lubricated to prevent direct metallic contact between the rolling elements, raceways and cages, to prevent wear and to protect the bearing surfaces against corrosion.

Checking the condition of bearing seals and performing routine maintenance on most motors is easy when the motor is readily accessible. But what about submersible pumps? By the nature of their name, submersible pumps are designed for submerged installation, normally in a wet well as part of a lift station (where wastewater is pumped to a higher elevation so that gravity can be used to bring it to the treatment plant). Click here for more information on lift stations. Accessing the bearing seals on a regular basis is not easy.

Therefore, most submersible pump manufacturers recommend the use of a seal leakage relay to monitor for potential leaking seals.

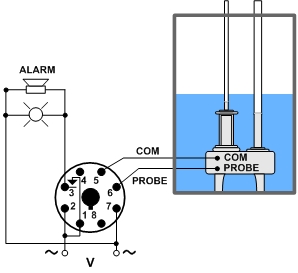

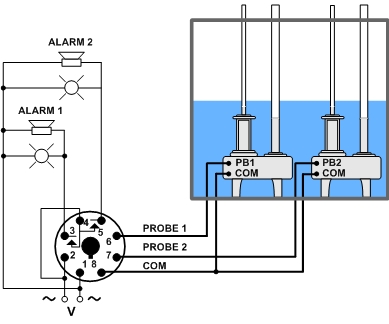

Operation: Two wires from the seal leakage relay are connected to a resistance-sensing probe in the pump seal cavity and the grounded motor housing or across two probes to monitor for seal leakage using a low-voltage DC signal. The sensitivity setting is normally set per guidelines from the submersible pump manufacturer. If the seal starts to leak, contaminating fluid enters the seal cavity. This lowers the resistance between the internal probe and the common connection. When the resistance drops below the user-adjustable sensitivity set-point of the relay, the output relay energizes and the LED turns Red ON. The relay output can be used to give an alarm indication of a leaking seal whether that be an indicating light, an input to a PLC or to a phone dialer.

|

|

|

|

Single Channel Seal Leakage Relay to Monitor One Pump |

Dual Channel Seal Leakage Relay To Monitor Two Pumps |

Remember, the application for seal leakage relays is very narrow—they are only used on submersible pumps. If the pump is readily accessible, i.e., above ground, there is no need for a seal leakage relay.

But there are tens of thousands of submersible pumps for water & wastewater applications all over the country. And there are hundreds of panel shops who build controls for submersible pumps in this market.

Recent Articles for:

Seal Leakage & Temperature Relays

- Mar2017 Replacing a Crouzet PNR110A with a Macromatic SFP120A100 Seal Leak Relay

- Feb2017 Where are Seal Leakage Relays Used?

- Jan2017 Macromatic’s New TCF Series Drop-In Replacement for MPE’s PMR1 & PMR3 Has More Advantages

- Aug2015 Connection of Pump Seal Failure (Seal Leak) Relays in Submersible Pump Applications