Implementing Communication in Smart Connected Control Systems

Learn more now about the new Macromatic PC1MDUL Phase Monitor Relay with Communication >

Simplify with HMI Displays

Macromatic PC Series phase monitor relay empowers Human Machine Interface (HMI) displays with a rich variety of data including system faults, line voltages, and operating frequency. Information from the phase monitor and other sources can be combined and displayed on the HMI, safely away from hazardous environments, live circuits, and moving parts.

Information from the PC Series can be displayed within existing HMI screen layouts to bring more data to operators without the need for separate panel indicators, stack lights, or flashers. Information can also be used in screens customized to application needs making critical information available at a glance.

PC Series phase monitors operate as Modbus TCP Servers. Clients devices such as PLCs request data from the server and the server replies back to the client with the requested information.

The PC1MDUL is connected by a standard Ethernet patch cable from its Ethernet port on the front face to an Ethernet switch or directly to the PLC (if supported). The PLC will pull data from the PC1MDUL and route it to the HMI to be displayed.

Remote Data Saves with SCADA

Remote Supervisory Control and Data Acquisition (SCADA) monitoring operations can be optimized using data from the PC Series phase monitor relay. Real-time fault status can be used to detect and alert support personnel of problems at remote installations.

Technical staff can troubleshoot faults using the fault type, voltage, and frequency information from the PC1MDUL without needing to travel to the installation site. Service personnel can be dispatched with proper tools and replacement parts to correct the problem reducing downtime and travel costs.

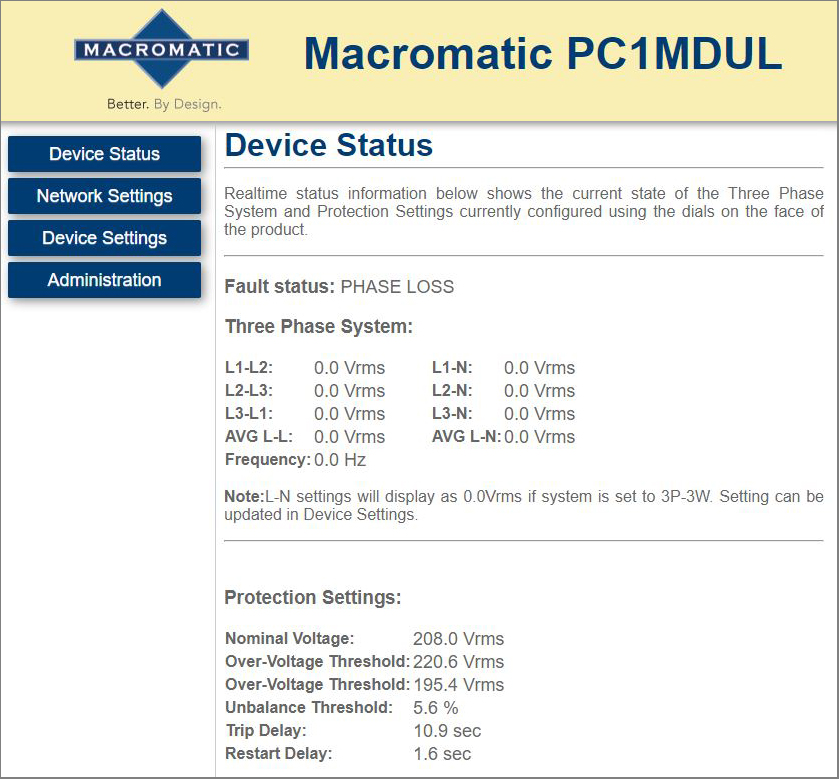

If remote communications to the site are down, on-site personnel can still access valuable real-time troubleshooting information by accessing the built-in webserver on board the PC1MDUL from a laptop, phone, or other device.

Simply plug-in or wirelessly connect to the Ethernet network of the control system and enter the device name or IP address into a web browser for instant access.

Controls without Borders

Cloud Computing and big data concepts are transforming traditional control, monitoring, and maintenance.

Machine learning and Artificial Intelligence(AI) can be leveraged within cloud platforms to do predictive maintenance, trend analysis, and optimization powered by massive amounts of data.

The potential of these technologies is huge, but they are limited by the amount of data provided to them. Building IOT Devices into control systems will create a wealth of data from your processes, systems, and machines for use in the cloud.

Network infrastructure such as routers and gateways provide a secure path for IOT devices to bring their information to its end destination, whether it’s the plant control room, remote monitoring center, or the cloud for advanced analytics.

Distributed installations that are connected using the Internet require remote configuration and management. For this reason, the PC Series device settings can be managed both over Modbus TCP and using the built-in webserver allowing changes to be made from anywhere.

Learn more now about the new Macromatic PC1MDUL Phase Monitor Relay with Communication >

Recent Articles for:

Three-Phase Monitor Relays