Barrier Relays vs. Zener Barriers in Intrinsically Safe Control Circuits

Intrinsically safe control circuits provide a safe and cost-effective method for interfacing electrical control devices that span across hazardous and non-hazardous locations. Safety is ensured at these interfaces using intrinsically safe barrier devices.

Two of the most common barrier devices are Zener Barriers and Barrier Relays (such as the Macromatic ISDUR4). Intrinsically Safe Zener Barriers limit the voltage and current of an existing electrical signal in the control circuit to ensure safety. Intrinsically Safe Barrier Relays build upon the Zener barrier by integrating additional features that reduce cost and simplify circuit design process.

Zener Barriers

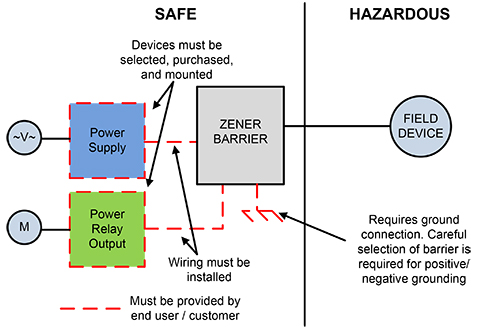

Using a Zener Barrier properly in the control circuit provides intrinsically safe protection. Completing the control circuit design requires a power supply, load, and a ground connection. Careful attention is needed when selecting and installing these components to ensure intrinsic safety is maintained, including the coordination of Entity Parameters of the Zener Barrier, cable, and Field Device. Design consideration for Zener Barriers include maximum supply voltage, maximum supply current, and acceptable series resistance. Grounding must also be considered as the Zener Barrier must be grounded, and all signals passed through the device will be ground referenced. A typical application of a Zener Barrier being used to protect a motor control circuit is shown below. The power supply, power relay(load), and ground connection must be selected in addition to the Zener Barrier.

Barrier Relays

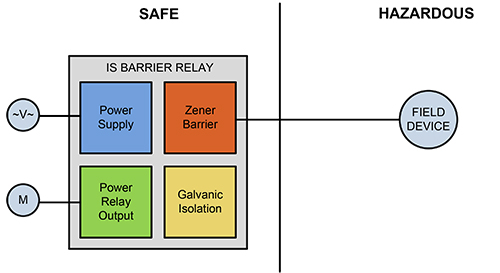

Barrier Relays offer the protection of a Zener Barrier without the design complexity and certification headaches of piecing together your own intrinsically safe control circuit. A Barrier Relay begins with a basic Zener Barrier. To this a power supply and output relay are integrated inside the device. Finally, galvanic isolation is provided eliminating the need for a ground connection. The Barrier Relay creates a safe signal to be sent into the Hazardous Location, reads the state of the field device, and sets the output relay according the to Field Device’s state allowing the control of a load device all in one easy to use device.

A typical application of a Barrier Relay is protecting a motor control circuit. The need for power relay, power supply, and ground connection are eliminated.

Summary

Intrinsically Safe Barrier Relays can provide a better solution for many Hazardous Location Control Circuits. Supporting components are fully integrated and complex safety certifications already completed saving time and reducing risk.

The Macromatic ISD & ISE Series Intrinsically Safe Barrier Relay are a safe, reliable, and cost effective devices. The universal input voltage range (102-132VAC and 10-125VDC) together with optional time delays and logic inversion features make an ideal barrier relay solution for most applications.

Learn More: Hazardous Location Classification

Recent Articles for:

Intrinsically Safe Barrier Relays