An Overview of Hazardous Locations

Intrinsic Safety: Factors Required for a Fire or Explosion

When electrical equipment is used in or near hazardous environments, there is a possibility of that a fire or explosion might occur. These hazardous areas have flammable gases or vapors, flammable liquids, combustible dusts, ignitable fibers or flyings.

These hazardous (or classified) environments are currently classified using two systems: the Class/Division system, used predominately in the United States, and the Zone system, generally used in the rest of the world.

What’s Needed for An Explosion?

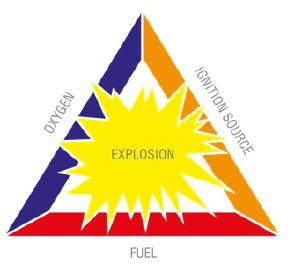

The most common types of reaction are between flammable gases, vapors or dust with oxygen in the surrounding air. As a rule, three basic requirements must be met for an explosion to take place in atmospheric air:

1. Flammable substance

2. Oxygen

3. Source of Ignition (a spark or high heat)

Note: both the flammable substance and the oxygen must be present in the correct mixture for the explosion to happen.

How is the Explosion Controlled?

The objective of selecting electrical equipment and the means of installation is to reduce the hazard of the electrical equipment to an acceptable level. The most certain method of preventing an explosion is to locate electrical equipment outside of hazardous (classified) areas whenever possible. In situations where this is not practical, installation techniques and enclosures are available which meet the requirements for locating electrical equipment in such areas. These methods of reducing hazards are based on the elimination of one or more of the elements of the ignition triangle discussed earlier.

Three principles ensure that electrical equipment does not become a source of ignition:

1. Contain the explosion: measures must be taken to ensure the explosion cannot spread to the surrounding

atmosphere (explosion-proof enclosures or conduit & cable seals)

2. Isolate the hazard: the surrounding atmosphere is prevented from entering the enclosure by maintaining a

positive pressure of inert gas or clean air within the unit (pressurization and purging, oil immersion & hermetic

sealing

3. Limit the energy: potentially explosive mixtures can penetrate the enclosure but must not be ignited. Sparks

and raised temperatures must only occur within certain limits (intrinsic safety)

All Macromatic IS Series Intrinsically Safe Relays follow the third principal: limit the energy utilizing an intrinsically safe circuit.

Hazardous Location Classifications

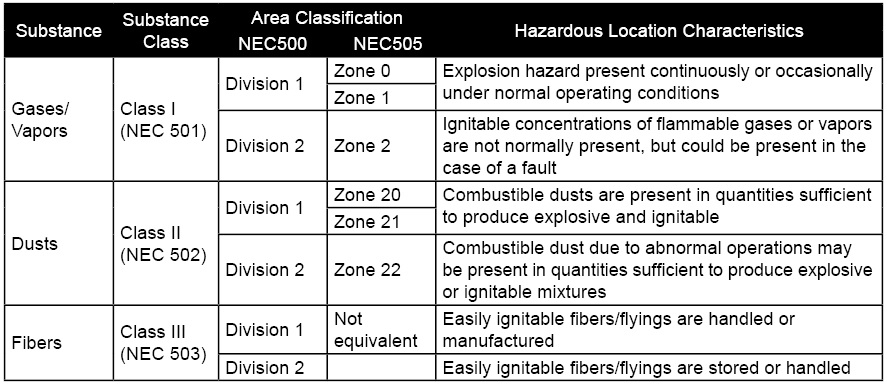

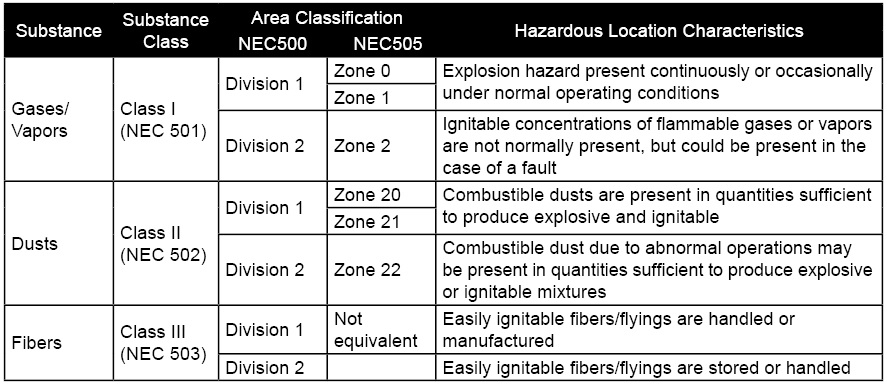

Standard classification systems provide a concise description of the hazardous material that may be present along with the probability of it being present so that the appropriate equipment may be used and safe installation practices followed. In North America, the classification system most widely used is defined by the NFPA Publication 70, NEC and CEC. They define the type of hazardous substances that is or may be present in the air in sufficient quantities to produce an explosion. The NFPA establishes area classifications based on Classes, Divisions and Groups which are factors combined to define the hazardous conditions of a specific area.

The table below summarizes the various hazardous (classified) locations:

These are the Hazardous Location Classifications for the Macromatic ISD & ISE Series of Intrinsically Safe Relays:

Class I, Div 1 (Zones 0 and 1 in Canada), Group A, B, C, D

Class II, Div 1 (Zones 20 and 21 in Canada), Group E, F, G

Class III, Div 1

The Macromatic ISD & ISE Series of Intrinsically Safe Relays have been tested and approved for listing under Underwriters Laboratory (UL) 913 Intrinsically Safe Apparatus and Associated Apparatus 8th Edition. The Macromatic ISP Series of Intrinsically Safe Relays have been tested and approved for listing under Underwriters Laboratory (UL) 913 Intrinsically Safe Apparatus and Associated Apparatus 6th Edition. The input or inputs to these devices have been approved for use in all Classes, Groups and Divisions.